What is the Use of Zinc Phosphate?

Zinc Phosphate Coating is essential in most of the applications where finished work pieces must have high corrosion resistance and conspicuous paint adhesion. The zinc phosphate coating can improve the physical appearance of finished goods through the formation of a uniform grey or black appearance. This process is also a cost-effective alternative to Zinc and nickel plating.

How does zinc phosphate prevent corrosion?

Zinc Phosphate is a calcium modified crystalline coating on a metal surface which is created by chemical reaction between the metal substrate and the Zinc Phosphating solution. The resultant coating forms a network of fibrous crystals which facilitates paint adhesion and prevents corrosion development.

What is surface activation in phosphating?

It is a process of controlling the size of phosphate crystal. The surface activators are used to obtain thin, compact and fine-grained phosphate coating on metal substrate which will enhance Corrosion resistance and paint adhesion. It is also called as grain refinement.

SCOPE

HAMBOND-Z is designed to produce Calcium Modified micro-crystalline zinc phosphate coating on Iron and steel surface in a hot bath at a temperature of 70 to 80°C. The phosphate coating so produced is highly corrosion resistant and provides a good base for paint adhesion. The coating is composed of calcium modified Zinc Phosphate crystals which prevents the attack of atmospheric oxygen and hold the paint roots.

Essential Stages of the Process

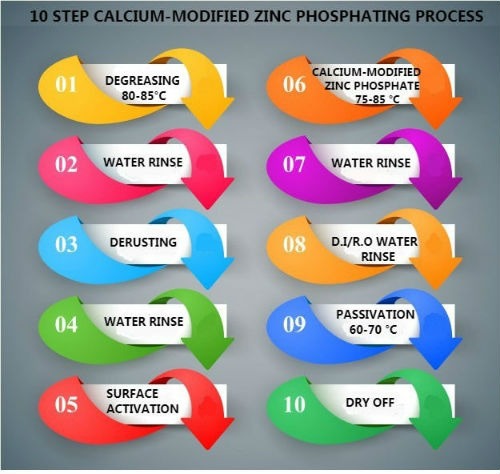

The calcium modified zinc phosphating process comprise of 10 stages. A typical 10 stage process is shown in the diagram below,

DEGREASING

It is the mandatory initial treatment of a substrate before the application of phosphate coating. In this stage, oil, grease, waxes and dust are cleaned from a metal substrate which can greatly reduce the development and performance of a Calcium-Modified Zinc phosphate coating. Majority of coating failures are caused by poor or insufficient degreasing of a substrate. Therefore, careful analysis of chemical concentration and contaminants in the tank is essential for the continuous production.

WATER RINSE

It is essential to prevent drag out of previous cleaning stage which can pollute the next coming stages.

DERUSTING

It is also an integral part of surface treatment which is not only used to eliminate rust and mill-scales but also generates metal surface profile which assists in the development of subsequent Phosphate coating.

SURFACE ACTIVATION

In this stage, grain refiners are added in the activation bath to reduce the size of the phosphate crystals which decreases the porosity of phosphate coating and improves its corrosion resistance. In this treatment, grain refiners are physically absorbed in the metal substrate which causes ion exchange between the refiners and the zinc ions when the activated substrate introduced in the zinc phosphating bath. These ion-exchanged particles not only provide crystallographic plane but also enhances crystal formation and epitaxial growth which furnishes thin and compact phosphate coating.

CALCIUM MODIFIED ZINC PHOSPHATE COATING

Finally, the substrate will be introduced in the Calcium-Modified Zinc phosphate solution (HAMBOND-Z) for 10-15mins which yields fine grained thin and compact phosphate coating. The calcium ions present in the phosphating bath also assist in reducing the size of phosphate crystals. The coating develop in this treatment exhibits superior corrosion resistance and provide excellent paint adhesion.

D.I /R.O WATER RINSE

Now the substrate should be thoroughly rinse with low T.D.S Water which could be filtered D.I (De-ionized) OR R.O(Reverse Osmosis) water. In order to eliminate residual compounds and insoluble salts which can diminish the performance of subsequent organic finishes such as Powder or Liquid Paint.

PASSIVATION

This stage is highly recommended due to its ability to seal micro cavities and voids in the crystalline phosphate coating which greatly increase the corrosion resistance of the substrate. Besides, it has slightly acidic nature which works well with majority of paint resin systems and improves paint bonding.

DRY OFF

Now the substrate must be completely dried off with the help of warm air blowers in the drying oven to eliminate surface moisture which can accelerate the process of atmospheric corrosion.

ADVANTAGES

- Calcium Modified Zinc phosphate coating (HAMBOND-Z) provides adequate Corrosion and wear resistance due to the presence of heavy metal ions.

- It is anti-galling coating which may not flake or peel off.

- The crystalline coating provides excellent paint adhesion

- This zinc phosphating bath generates very small amount of sludge

- Frictional effect of continuous moving parts will be minimized

- The coating eliminates light metal scratches which are formed during metal working process