ZINC PHOSPHATE CONVERSION COATING

Phosphate Coating system is the most extensively used metal treatment process for Iron, Zinc and steel surface. Owing to its affordability, efficiency and ability to provide outstanding corrosion protection, wear resistance, paint adhesion, and lubrication properties, it plays a vital role in the automotive, switch-gear,fabrication and appliance industries. Although it is known to be in use since late 1980s, but the low temperature Zinc Phosphating process has become more prominent in the contemporary world due to inflating energy prices.

What is a Zinc Phosphate Coating?

Zinc Phosphate coating is a slightly porous poly-crystalline coating which not only provide outstanding corrosion resistance but also an excellent base for subsequent organic coatings such as paints, oils, lacquer and waxes. It is a cost-effective alternative of Zinc plating. Phosphate coating is generally specified in coating weight rather than coating thickness. The coating weight of the phosphate coating is in range of 6-8g/m2. This coating provides excellent corrosion resistance and it can withstand 100-150 hours of salt spray test alone. The aforementioned coating also reduces break-in wear on adjacent moving parts. Besides, it improves torque-tension relationships and provides anti-galling and lubrication effect during cold forming processes such as deep-draw extrusions.

SCOPE

FINBON is designed to provide a low temperature Zinc Phosphate coating on iron, steel and zinc surface. The system works ideally at room temperature within the range of 10°C to 40 °C. The zinc phosphate coating so developed provides a network of fibrous crystals. These crystals facilitate the excellent adhesion of paint to the base metal and inhibit corrosion development.

PROCESS SYNOPSIS

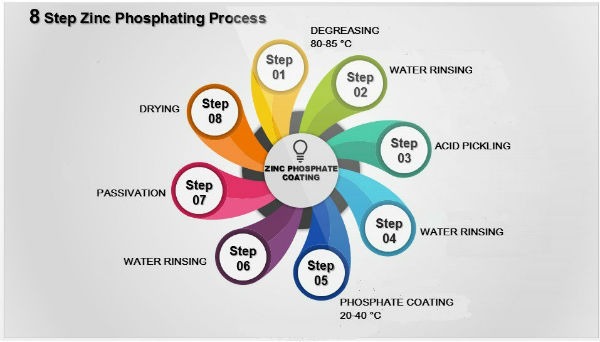

Usually, Zinc phosphating process consist of 8 stages but some stages can be included or excluded depending upon the condition of the substrate. A standard 8 stage phosphating process has been shown in the figure below,

Degreasing

It implies removal of surface contaminates such as Oil, grease, dust and waxes. It is the crucial prerequisite for subsequent Zinc Phosphate Coating. Majority of coating defects are culminated due to poor cleaning or degreasing. Effective degreasing can be achieved through potent solvent or alkaline cleaners. However, mechanical and heat acceleration (approx. 80-85°C) are required as an ancillary support.

Water Rinsing

It plays an instrumental role in eliminating surface contaminants and preventing drag out of chemicals used in the previous stage which may taint the subsequent stages.

Acid Pickling

It is a surface treatment which is used to clean rust or mill scales from the substrate. The chemical used in this stage comprise of strong inhibited inorganic acids which converts ferrous oxides into water soluble salts.

Low Temperature Zinc Phosphate Coating

Now this practically clean surface is subjected to zinc phosphate solution (FINBON) which forms insoluble inert poly-crystalline zinc phosphate coating which not only provides corrosion resistance but also greatly improves paint adhesion to the substrate. The aforementioned solution can be applied through dip or spray at 10-40 °C

Post Rinsing

Now the coated surface should be thoroughly rinsed with demineralized water in order to remove phosphate residue and other soluble salts which can cause blistering and flaking of subsequent organic finishes.

Passivation

Phosphate coatings are slightly porous which contain intercrystalline spaces or voids. These voids can affect the corrosion resistance of the substrate unless they are completely sealed. Therefore, dilute passivation solution is used to seal off these voids or gaps.

Drying

After passivation the substrate must be dried off in order to eradicate moister from the surface which could be detrimental for subsequent organic coatings.

BENEFITS

• FINBON provides adequate wear resistance due to the presence of heavy metal ions.

• It is an energy efficient process because system works ideally at 20 to 40c which reduces pre-treatment cost approximately 40-50% as compared to conventional Phosphating processes operating at higher temperature.

• The chemical consumption of FINBON is reported to be 40 to 50% less then the conventional phosphating chemicals working at higher temperature.

• It provides good corrosion resistance and excellent paint adhesion with the base metal.

PROPERTIES

• It is suitable for iron, steel and zinc substrate.

• It forms a small amount of sludge.

• The coating develops a non-conducting bond between the base metal and the paint.

• FINBON can be used for both spray and immersion applications.

• It forms a chemically inert layer on metal surface which makes it suitable for electrophoretic lacquering.